Promotion of automation and labor-saving at job site by a consistent production with design, production and robot teaching.

Making total system proposal to optimize the total production line by listening to user's request and situation.

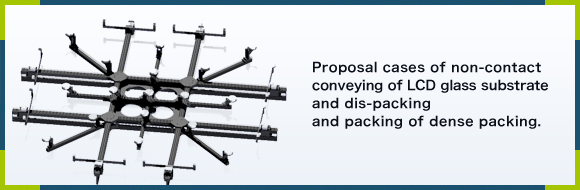

Non-contacting conveying system for LCD glass substrate(float chuck hand & conveyor)

Non-contacting conveying system for LCD glass substrate(float chuck hand & conveyor) LCD glass substrate un-packing/packing of dense packing

LCD glass substrate un-packing/packing of dense packing

Products outline

Float chuck hand

Float chuck hand

Sucking glass substrate by air without contacting. Transferring it between production lines.

Floating conveyor

Floating conveyor

Floating glass substrate on the conveyor by air without contacting it, and conveying it.

Problems before development

- At present, roller conveyor type is still popular in LCD glass substrate conveying equipment.

This non-contact way can convey glass substrate without scratch on inspection to packing line after washing process where roller type has a problem, then, improvement of product quality can be possible when shipping. - Dealing with G8 through G10 in next generation standard of LCD glass substrate.

- Performance is improved than existing non-contact conveying system (less vibration. more floating ability).

The point to develop

Non-contact robot hand using the principle of Bernoulli.

Using negative pressure generated by air-exhausting, sucking glass substrate.

- It is possible to convey glass substrate with less vibration, holding down a pulsation, compared to an old type.

- Making it possible to save energy by keeping floating ability and holding exhausting air.

- Full-automation of glass substrate transferring between lines.

- Capability to deal with next generation standard(G8-G10)of glass substrate considering enlargement-design.

Product outline

This is a system to un-pack from pallet. Dense pack specialized in conveying for LCD glass substrate and to pack it after washing, inspection process.

This is a system to un-pack from pallet. Dense pack specialized in conveying for LCD glass substrate and to pack it after washing, inspection process.

It is possible to take out and accumulate glass and inserted paper.

This system can be used at both production lines such as LCD glass substrate, LCD panel.

(Unpacking equipment, dense an packer, packing equipment, dense packer)

Problems before development

- Dealing with irregular performance. (Modification of the pitch-gap)

- Improvement of line efficiency.(more speedy, labor-saving)

- Dealing with the next generation standard (G8-G10) in glass substrate conveying.

The points to develop

Automatic optimum pitch calculation is possible by robot searching function.

- Securing top-share in Taiwan market in packing for dense pack/system. (more than 50% share)

- Adopting our equipment specification as world standard.

- Drawing out the fastest processing ability in the world.

(G8:18sec/piece, G5:010sec/piece)